Further

Modifications of the CG-5 mount drive

By Pawe³ £añcucki, Pawel.Lancucki@pl.ibm.com

Here I described

modifications of the original duaI-axis drive for use with the CG-5 mount from

Celestron.

Electronic drive

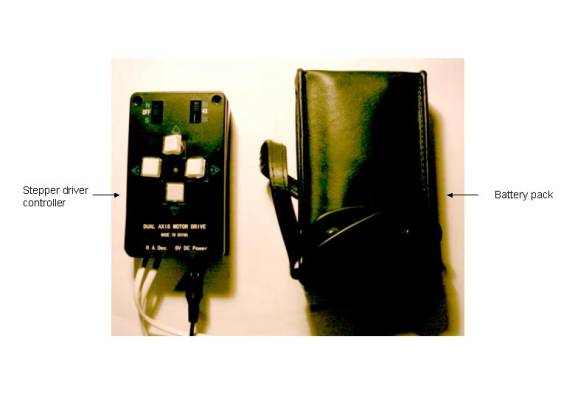

Original dual axis drive

from Celestron consists of four main parts: two stepper motors with gear boxes;

hand controller, which includes all the electronics and connectors and power

supply in a form of a battery box accepting 4 R20 (D type) 1.5V cells.

Components of the original

drive are shown below:

The drive is quartz

controlled and gives good accuracy for visual use. Main drawbacks of the drive

are:

- Backlash in gear trains;

- Lack of provision for use of external power

sources, like car battery or wall transformer;

- Hand controller usually cannot be conveniently

placed due to short leads to motors and to power supply.

Not a lot can be done with

the gears, so I decided to focus on rebuilding / rearranging the electronic

parts. I also decided not to play with the original printed circuit board

(PCB), but rather to connect external components to it. Also, I decided that

components build should be (as far as possible) compatible with a motorised /

computerised telescope drive as described by Mel Bertels.

The new electronic parts

consists of three main components (apart of the motors):

- Power supply

- Hand controller

- Stepper driving circuit

The

components were build exactly in the order described above to minimise any time

the drive is non operational – as described in the following text. The circuits

described below are very simple. The tools needed are those of a radio-amateur

and can be readily purchased in some stores (e.g. Radio Shack). I used a couple

of screwdrivers, small hand tools to cut or bond wires and component leads, 15W

soldering iron, small electric drill, fine files to make holes and universal

electronic multi-meter (I use mostly voltage, current and resistance settings

as well as a circuit continuity tester).

Just a word of warning – any

changes you do to any electronic components may and will violate the manufacturer

guarantee and therefore will be done at your own risk. If you are not confident

you can modify electronic components, ask a friend or limit yourself to the

power supply box only!

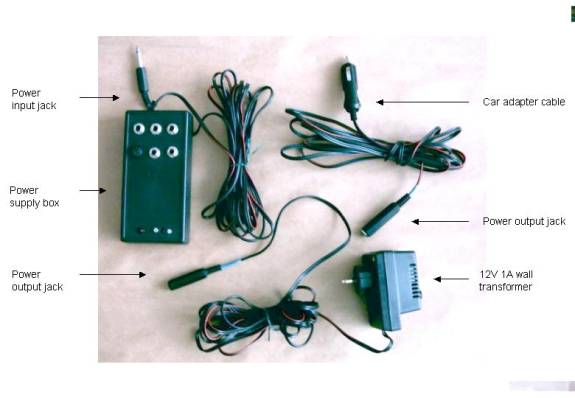

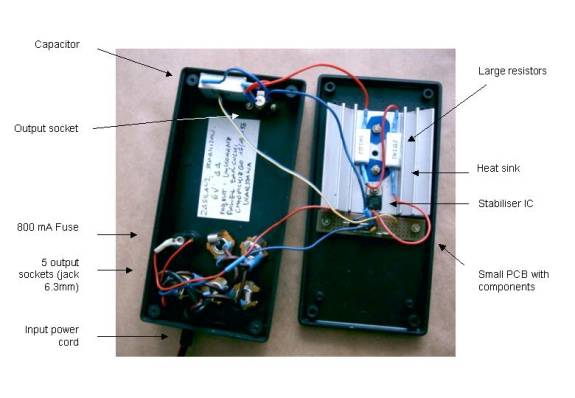

Power supply components are shown below:

Power can be sourced from

220V mains (European standard), from 12V car battery or from any battery pack

capable of driving the scope through the night.

Celestron dual axis drive

requires 6V at approximately 500mA. However, a stabiliser IC cannot be

connected to it directly – the drive “hangs up” with higher power consumption,

ant this may cause stepper driving transistors to burn. Apparently the original

circuit uses internal resistance of the batteries to limit motor coil current,

so I taken a provision to include additional 2 Ohm resistance in the power

line.

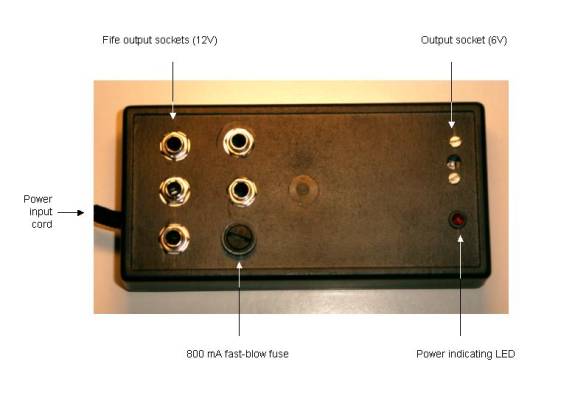

At this time, I also decided

to use 6.3mm mono Jack plugs and sockets as a standard for all power supplies.

One 6.3mm mono Jack plug on a 3 m speaker cord (2 x 1.5mm2) provides

supply to the unit. Five 6.3mm mono Jack sockets are mounted on the front cover

and can be used to provide supply to other devices, like dew heaters, mirror

cooling fan, small CCTV camera etc. You may opt to increase the rating of the

power cord depending on your particular power needs, however, high power

consumption accessories or accessories generating electromagnetic noise should

use separate power supply. Front of the power supply box looks as follows:

The entire power supply box

is housed in a small (ca 8 x 14 x 3 cm) plastic “project” box. Four mono “jack”

sockets are not fuse protected and can be used to supply power to auxiliary

devices.

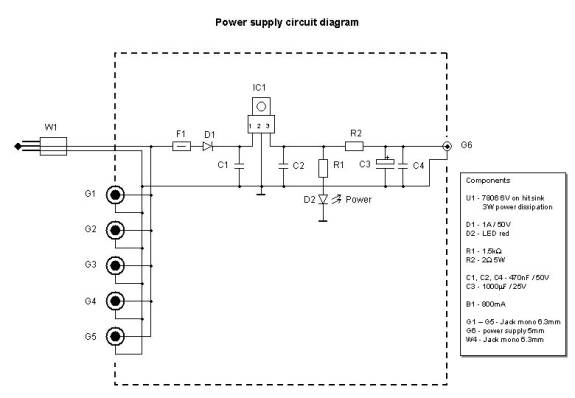

The power supply box circuit

diagram is shown below:

Power supplied to the drive

electronics is protected by 800 mA fuse F1. Diode D1 - 1A/50V - protects the

circuit from reverse polarity in input lines. Power is the conditioned by an IC

stabiliser IC1 - LM7806 - down to 6V. It should be mounted on a heat sink to

dissipate 3 – 5W of power. In my case, I have used ca 100 cm2 heat

sink with tree-like fins, which heats warm in use but actually never overheats

even after many hours of use. Two small capacitors C1 and C2 – 470nF/50V are

necessary to prevent unwanted oscillations of the IC. Small red LED diode D2

fed by resistor R1 - 1.5kW

1/4W - is mounted on the front cover and confirms that the power is on. Two 1W resistors rated 1W each (shown as R2) simulate the

internal resistance of the battery pack, and output capacitors C3 – 1000mF/25V and C4 – 470nF/50V are necessary to moderate

any current spikes caused by stepper switching circuit. Internal electronics is

shown here:

Finally, power is fed to the

stepper driving circuit by 1.5m of 0.5mm2 wire with standard “power

supply” plugs on both ends. In my case, I used a spiral wire form an old headphone

set. However, I may opt in future to exchange these plugs because the standard

plug tends to slip out of the socket in the stepper controller!

Any voltage between 9 and

15V can be applied to this unit, however it should be compatible with power

requirements of any auxiliary devices connected to jack sockets. Direct

connection to car battery (12V) or 12V wall transformer (unregulated) is

usually adequate. To complement the power supply box I have made a car lighter

to jack socket adapter cable and one 10 m (30 ft) extension cable, which

extends the use both in my yard and in field. Also, a jack socket was mounted

on the end of cable from a commercial 12V wall transformer to provide supply

while using the scope in my backyard. Warning – I always place the wall

transformer in house and use 10 m extension cord. Bringing a wall transformer

outside may create a risk of electric shock!

You can prepare the power

supply box without any changes to other components, while you continue to use

the battery pack. Once the power supply box is complete, you can start to use

it immediately even if you do not plan to make any other modifications. Here,

the power is supplied from a wall transformer through the power supply box to

the original hand controller:

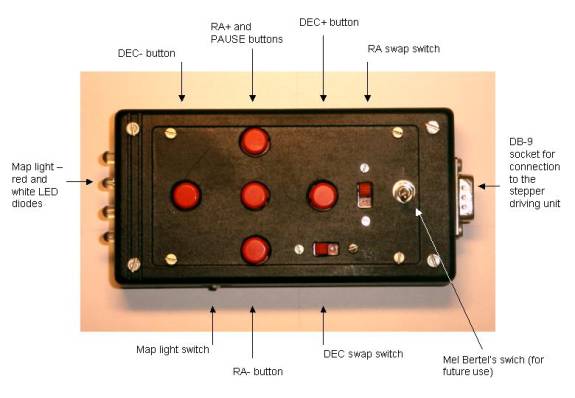

Hand controller is slightly more complex. The front panel is shown

below:

The main features are:

- Four direction buttons (N, S, W, E or RA+, RA-,

DEC+ and DEC-), which actually duplicate the direction buttons on the

original controller box. These buttons operate at the speed set by the

switch at the original controller box – 2x, 4x or 8x.

- Pause button. I decided to include it for

astrophotography use because the original 2x speed switches the RA stepper

motor into opposite direction and all backlash in the gear train prevents

the mount from reacting quickly. It will also operate as an “enter” button

while connected to the Mel Bertel’s computer controlled drive.

- Two direction control switches. The simply

reverse operation of pairs of direction buttons to make the unit more

intuitive to use.

- One three position switch which does not have a

function allocated at the moment and is build in for future use with Mel

Bertel’s computer controlled drive.

- One three position switch which activates map

lights. I have used two bright red LED diodes to get “night vision” red

light preserving eye accommodation, and two bright white LED diodes to

read colour coded maps. Order of switching is OFF à RED à White.

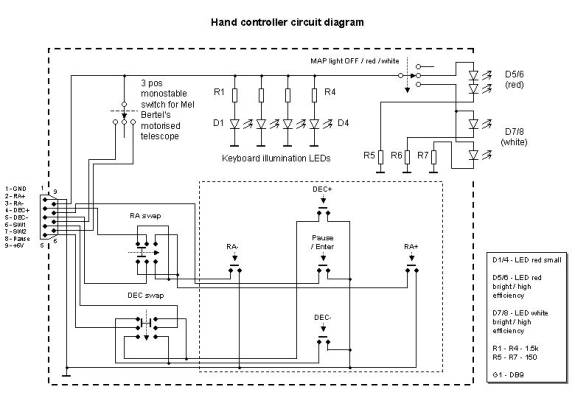

The hand controller circuit

diagram is shown here:

All buttons operate by connecting appropriate output line to

ground, while in a “non-active” state, output lines are “floating”.

Fife small mono-stable press

switches are used for direction and pause buttons. Pause button is connected

directly to the output socket. Direction buttons are grouped in pairs (N+S and

W+E) and connected to two switches, which reverse operation within each pair.

Output lines of the switches are connected directly to the output socket.

The three-position switch

output lines are connected directly to the output socket.

Another three-position

switch is used to activate LED map lights. Two diodes are used for both red D5

/ D6 and white light D7 / D8. Configurations of diode pairs and current

limiting resistors depend on required diode voltage and were adjusted to get

20mA current through each diode – this gives a decent brightness without

possibility to burn the diode. In my case, red LED diodes are connected in

series, while white LEDs are connected in parallel, with separate current

limiting resistors. In my case, all resistors turned to be 150W. Power supplied to diodes by one of the connecting

lines is connected to the stepper driving circuit. The voltage may vary when

steppers are in the sleeving mode, but the changes in LED brightness are negligible.

Finally, four small LED

diodes D1 to D4 with current limiting resistors R1 to R4 (all 1.5kW) are connected directly between power supply and

ground. They glow dimly in the night and provide very dim backlight to the

controller buttons. Actually, you may opt to use resistors of even higher

value, depending on the required level of button backlight. Values shown here

were tested in a decent dark, but not ink-black environment.

All resistors are rated

1/4W.

A DB-9 “computer type” male

socket is used to output the controller lines. The individual pins’ functions

are as follows: 1 – ground, 2 – RA +, 3 – RA-, 4 – DEC+, 5 – DEC-, 6 – three

position switch pos1, 7 – three position switch pos2, 8 – pause, 9 – power

supply 6V.

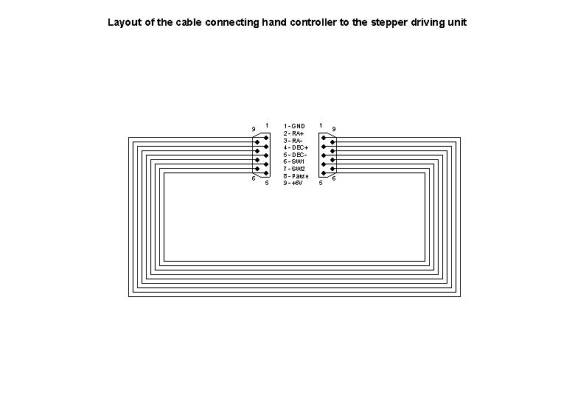

A custom made cable with 9

lines and male / female plugs on both ends connects the controller to the

stepper drive. I used soldered joints, which are very reliable. I decided to

make the cable in a way which enables easy replacement or extension – see

below:

Most of components were

mounted directly on a universal printed circuit board 100 x 60 mm, which is

held inside a black plastic project box 120 x 65 x 20 mm. This size is a good

compromise between ease of assembly and convenience of use.

Two direction reverse

switches and extra switch for computerised drive were mounted on the cover of

the box.

The order of operations was

as follows:

1

Select a plastic

project box which fits your hand and which will accommodate all components.

2

Select a universal

printed circuit board and cut it to fit inside the project box. Prepare

mounting holes / spacers to secure the board inside the box.

3

Select positions for

direction / pause buttons and mark PCB holes which coincide with centres of the

switches. Next, drive a thin (1.5mm) drill through the board while mounted to

the box – this will ensure that buttons will mat the holes after they are

soldered. Make button holes slightly oversized – for my 9.5mm buttons I made

10mm holes.

4

Cut or drill remaining

openings in the box – for direction reverse switches, MEL Bertel’s switch, DB-9

socket, 4 LED diodes and light switch.

5

In my case, I had to

cut or drill holes in the printed board to provide clearance for switches which

are attached directly to the box cover.

6

All drilling / cutting

should be completed before you start to assembly the electronics. While

assembling the electronic components, always check for fit to the prepared

holes / openings.

7

Carefully solder all

components – one at a time. I started with LED diodes as they must match the

holes in the box. Next – direction buttons, diode driving transistors /

resistors and small LEDs and their resistors. Finally, connect the components

which are mounted outside the printed board (direction reverse switches, MEL

Bertel’s switch and DB-9 socket) with short lengths of thin stranded wire – I

used small pieces cut off a 10 strand tape.

8

Check proper resistance

for the current limiting diodes before soldering the components – I did it by

just connecting diode and resistor to 6V power supply and ground leads carrying

these components in hands, while watching the readout of my mili ampero-meter.

Also, check all buttons / switches before assembly – they are quite difficult

to take apart from the PCB once they are mounted.

9

As I used an universal

PCB, there was a need to connect individual printed paths of the board. I made

these connections from cut-over resistor / diode pins (short ones) or from very

thin stranded and insulated wire (longer ones).

10

After soldering each

component, check for possible bridges between adjacent printed paths. In case

of doubt, check with resistance meter. All eventual bridges must be cleared

right on spot, as they will be even more difficult to remove after more

components are attached.

11

I always solder one

component or one group of components at a time and take few moments to test the

circuit. In case of any problem, it can be contributed to the most recent

mounted components. This is a very practical advice – I did quite a bit of

custom electronics development and it always pays to do as much testing as

possible at various assembly stages.

The entire controller can be

mounted in three – four evenings – one to do the machining and the rest to

solder and test the circuit. You can continue to use the original drive while

you build the hand controller, so there is no rush – just do it well.

Those who already know the

design of the Mel Bertel’s computer controlled drive have already noticed that

the hand controller is not entirely compatible with the drive – in particular

the buttons and switches do not operate in required way. I decided to make the

hand controller more suitable for the current use, while compatibility with Mel

Bertel’s computer controlled drive will be achieved by adding some ICs to

properly decode buttons and switches at a later stage.

Stepper driving circuit is the most tricky part, because you actually need

to play with the factory made PCB .

Also, you cannot use the drive while the original stepper driving circuit is

disassembled.

I decided to retain both the

original stepper driving circuit as well as its plastic housing. The add-on

components are mounted on a separate universal PCB, which is housed in another

plastic project box – a twin to the hand controller. The original driver box is

“piggy-backed” on the add-on components box (glued with double sided tape and

fixed by four M3 screws), both circuits are connected by a number of wire

strands which pass through a couple of holes between both boxes.

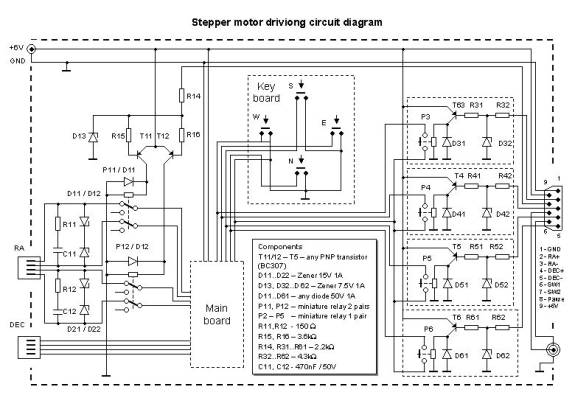

The stepper driving circuit

diagram is shown below:

Direction buttons (N, S, E,

W) of the hand controller drive four identical amplification circuit. I used

these amplifiers to make my circuit compatible with auto guiding units. In a

low input state, the driving unit must be able to sink less than 0.5mA –

typical MOS ICs can sink up to 2.5mA, while TTLs can sink up to 10mA.

Therefore, this unit is quite safe to use with commercial auto guiders.

I will describe operation of

the amplification circuit based on the RA+ line. Input line is connected to a

base of a low-power PNP transistor T3 through a network of two resistors R31 –

2.2kW and R32 – 4.3kW and a protective Zenner diode D32 – 7.5V 1A. This

circuit will ensure that the transistor is saturated (open) while the input

voltage is close to ground, but it will also protect transistor from damage in

case a high or low voltage is accidentally connected to the input line.

Transistor T3 operates miniature relay P3, which in turn duplicate the function

of the existing direction buttons. Therefore, the internal circuit of the stepper

driving circuit is separated from any voltages that may appear on the input

lines. Transistor is protected from any voltage spikes which can be caused by

turning on and off inductive load of the relay coil by a reverse polarised

diode D31. Normally open pairs of relays’ contacts are connected by pairs of

thin wire (cut from 10 wire colour tape) to the back of the button PCB from the

original controller. Make sure that RA and DEC buttons are not mixed. Actually,

it does not matter if you connect RA+ relay to the West or East button of the

stepper circuit – if the operation of the buttons is opposite to what you

desire, simply put the swapping switch on the hand controller in a second

position!

The pause button operation

is slightly more complex. Ideally, I should rather disconnect coil driving unit

from the micro-controller on the original PCB. However, I did not want to play

with the original PCB, so I used two small relays P11 and P12, which disconnect

two RA motor coils from the driving circuit. Suddenly switching the coil

inductance from the current supply generates voltage spikes that could over

time destroy small contacts of the relays. Therefore, on both coils I used a

spike protection circuit consisting of 150W 1/4W resistor R11(R12) and 470nF capacitor C11

(C12), connected in series. Furthermore, two 15V 1A Zenner D11/D12 (D21/D22)

diodes cut-off any over-voltage spikes.

Instead of simply

re-connecting the motor wires to the relays, I used two RJ-4 sockets – this

enables me to use any standard telephone cable as connection between the

driving box and stepper motors. Coiled telephone cables are by far more

convenient in use and also can be easily replaced in case of any damage!

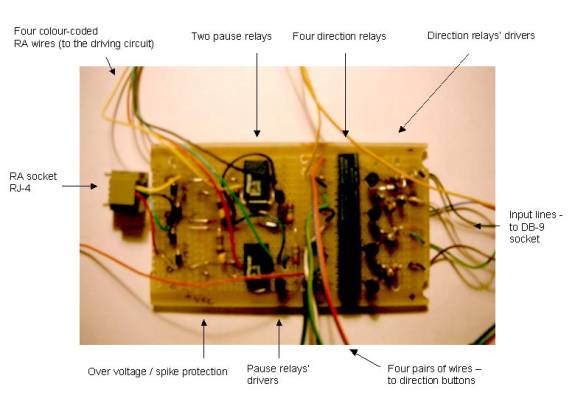

The whole stepper driving

circuit consists of two main components:

- original stepper driver (hand controller)

- relay board which houses all additional

components.

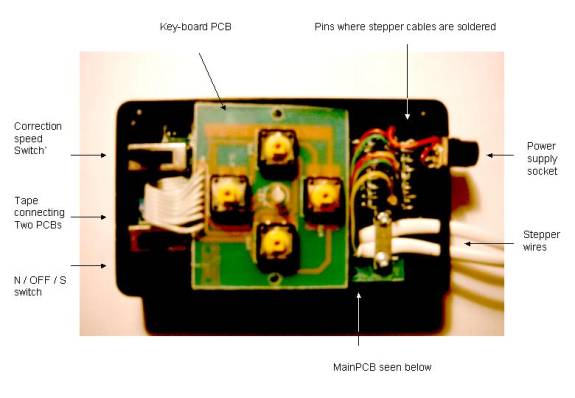

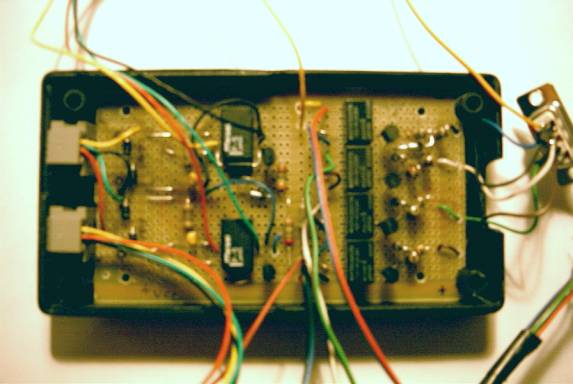

Close-up of the original

drive controller unit interior is shown here:

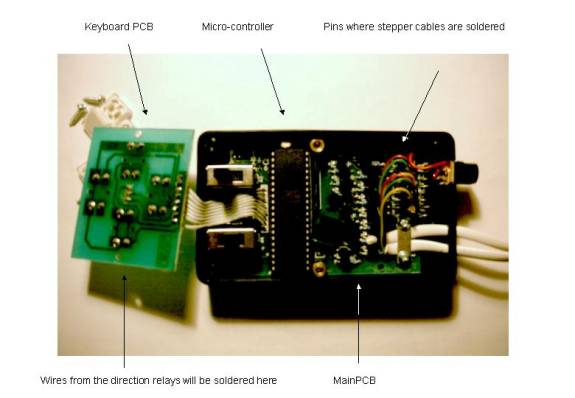

Here you can see it after

the key-board was removed:

And here there is a close-up

of the relay board:

Here is shown how it looks

inside the plastic box:

The order of operations was

as follows:

1

You do not need to play

with the original drive before the relay board is completed and tested – start

with it!

2

Select a plastic

project box which will accommodate all components. In my case, it was identical

to the hand controller box.

3

Select a universal

printed circuit board and cut it to fit inside the project box. Prepare

mounting holes / spacers to secure the board inside the box.

4

Cut and drill openings

for RJ-4 sockets (to motors) and for DB-9 socket (connection to hand

controller).

5

Lay the largest

components on the PCB. I opted to put relays in two groups – four relays which

operate direction buttons are mounted closer to the hand controller socket,

while two remaining relays which operate the pause function are mounted closer

to the RJ-4 connectors to motors. I left a lot of space around the relays to

mount other components (drivers / amplifiers, relay protection etc.).

6

Before soldering relays

check them for polarity - my pause

relays did not work until the driving voltage was applied to the coil in a

specific. Also, check which pins correspond to the relay contacts, which will

be opened and which closed before and after applying power supply. I used 6V

relays, which still operate safely while powered by a lower voltage (the supply

may drop by 0.5 to 1 volt due to the current consumption by stepper motors and

additional 0.4 volt for driving transistors).

7

If you have an

opportunity, check the transistors for their current amplification coefficient.

It should be at least 100 - 120, and preferably around 200 to ensure proper

operation of relays.

8

Connect two power

supply lines – red for positive and white or black (or any other, just remember

the colour) as negative.

9

Lay and solder all

other components. I started with direction relays. Again, I opted to assembly

one relay circuit at a time. After each section is completed, solder a short

coloured wire as an input line and test this section by connecting the input

line to the ground – you should hear the relay to click while switching. If you

don’t, check that particular section.

10

Attach pairs of thin

wires to the connecting contacts of the direction relays. It helps to use

colour-coded pairs from a 8 or 10 wire tape. Please note which colour

corresponds each relay and save this information until you connect this pairs

to the button board.

11

Solder all input lines

to the appropriate pins of the DB-9 socket. Also, remember to connect power

supply and ground lines to DB-9 socket – otherwise the hand controller would

not work!

12

Connect the RA RJ-4

socket to the pause relays. Please note the colour coding of the RJ wires. Red

and green wires should be connected to one relay while black and yellow to the second

– this pairs drive two stepper coils and need to be connected to the

over-voltage / spike protection circuit.

13

Connect a 4 wire tape

to the pause relays – each of 4 wires between the original controller and the

RA motor will be disconnected. Please use the same wire colours as the ones

which were just soldered from the RJ socket – this colours will be important

while you will connect these wires to the stepper driving board - this tape

will be later soldered to the output pins of the RA line. All these tapes and

wires should be quite flexible!

14

There are two pins (6

and 7) left on DB-9 socket – they correspond to the three position mono-stable

switch. You may leave them not connected – I opted to connect them (and power

supply and ground) to a small auxiliary socket, they can be used to control

motorised focuser in the future.

15

Apply 6V power to the

proper power lines (warning – this circuit has no protection from reverse

polarity of power voltage!) and perform a final check of the relay board – all

components should operate properly, hand controller buttons should cause relays

to switch. Check if the two wires in each pair get closed as you push hand

controller button, check if the RA lines get opened as you push pause button.

Also, LED diodes on the hand controller (keyboard back-light and map light)

should get lit.

16

Until at this moment,

you did not need to play with the original controller. But now it is the time!

17

Place the original hand

controller on a clean surface. Prepare plastic bag or box where you will put

various components and screws – you ill need them back to complete the

assembly! Also, prepare an anti-static bag or box to safely store the driver

circuit.

18

Please obey the

anti-static precautions while handling the drive components – any electrical

components can be easily destroyed by static which builds up on our body and

clothing. The best option is to use an anti-static wrist band connected to

ground by 1M resistor – I have purchased one some time ago in Radio Shack. Get

your soldering iron grounded and avoid touching electrical components on PCBs.

19

Carefully remove four

direction buttons’ caps, remove two screws mounting the power supply socket and

four screws holding the cover. Carefully remove the cover. You will see two

PCBs – four buttons and one two-coloured LED are mounted on the top board,

while the micro-controller and driving units are mounted on the “main” board on

the bottom. Both boards are connected by a multi-wire tape.

20

Remove two machine

screws holding the keyboard PCB. Locate and remove three remaining screws

holding the main board.

21

Locate ten pins where

all external cables are soldered. There are two stepper motor cables four wires

each and a pair of power supply wires. Consecutive pins are isolated. If you

look at the board while these pins are closest to you (natural position

according to the printed labels on the cover), RA cable will occupy four

leftmost pins, DEC cable four central pins and power supply two rightmost pins.

Please note on paper colours of wires which are connected to all pins – this

will be crucial later.

22

At this moment you will

have to disconnect both RA and DEC cables. Do it carefully and remove cables

from the controller box.

23

Carefully remove both

boards from the housing – pay attention not to destroy the tape connecting both

PCBs. Place the PCBs in an anti-static bag and put aside for a while.

24

Attach the bottom part

of the original controller box to the cover of the relay board housing. Pay

attention to ensure that you can attach the cover to the relay box – places for

screws must be left clear! Also, the RJ-4 sockets should be located close to

the output pins of the controller, while the DB-9 socket for hand controller

should be located closer to the keyboard side. I used some pieces of a double

sided tape to hold the together. Next, I drilled four 3mm holes through both

boxes. Four M3 machine screws and nuts are used to keep both boxes together – I

secured the nuts from turning out with small drops of paint.

25

Finally, drill two

large 10 – 12 mm holes between the boxes – all interconnecting cables will pass

through the holes. Clean the boxes (and your workshop) from any pieces of

plastic or dust left after drilling.

26

All drilling / cutting

should be completed before you continue to assembly the electronics.

27

Pass the wires and

cables from the relay box through the two holes up to the driver box. Do not

forget to pass the wires from the DEC RJ-4 socket as well!

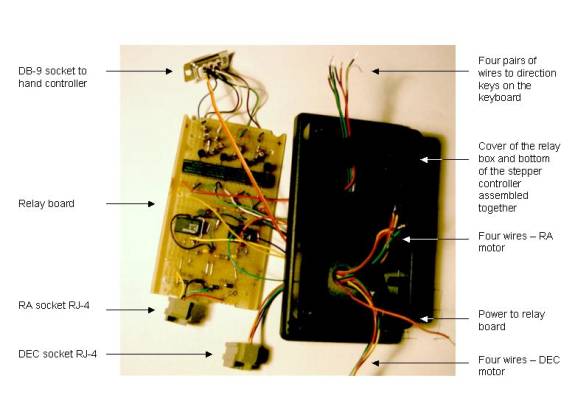

Here you can see this stage

of the project:

28

Take the driver PCBs

out of the plastic bag and put them back in the box.

29

Carefully solder RA and

DE socket wires to the appropriate pins on the driver PCB. Pay attention not to

mix RA and DEC wires and to solder colour coded wires to exactly the same pins

as before!

30

Solder the relays box

power supply directly to the power socket.

31

Solder pairs of wires

to the keyboard PCB. At there is no place to attach these wires on the

components side, solder them directly to printed paths below the direction

buttons. Ensure that RA and DEC pairs are not mixed (RA + or – can be connected

to any of the W or E buttons – you may only need to swap the button reverse

switch on the hand controller).

32

Now it is a time to

check the entire system. First, double and triple check visually that all wires

are connected properly. Check for any short-circuits between the power lines

and between the output lines of RA and DEC motors.

33

Connect the hand

controller to the DB-9 socket and connect RA and DEC motors to appropriate RJ-4

sockets. In my case, location of sockets correspond to the labels on the

controller cover.

Here you can see the stepper

driver side by side with the new hand controller:

34

Put the power switch in

central (OFF) position and apply power supply. Keyboard illumination LEDs

should get dimly lit. Hand controller buttons should operate appropriate

relays.

35

Switch the power switch

to N. RA motor should start (you can hear it). Check if the original buttons

still operate the RA and DEC motors. Next, check if the hand controller buttons

operate the motors as well.

36

Check if the pause

button stops the RA motor.

37

If everything went

well, you are ready to finally assembly the drive electronics. Otherwise,

switch the drive OFF and continue testing to isolate failed component or

connection.

38

Press the stepper

driving PCB back into it’s place. You may slightly pull the wires from the

relay board side – there will be lot of place left for wires in the relay board

box.

39

Attach three small

screws securing the main PCB. Attach the keyboard PCB using two machine screws

– be careful, you may need to press cables that are soldered on the soldering

side flat before you can tighten these screws.

40

Put the cover in place

and attach it using four screws. Attach power supply socket. Put button caps in

place.

41

Attach the relay board

inside the box. Make sure that all cables fit inside the relay box and attach

the cover with four screws.

42

Perform a final check –

just in case any wire or joint got broken during this final assembly stage.

The stepper driver

piggy-backed on the relay box:

Congratulations – you have

completed an important step – your modified dual axis drive was modified and is

ready to use! You may need to find a place to attach the drive to the tripod of

your mount. I opted to attach the drive electronics with a self-adhesive Velcro

tape, while the hand controller is held in a bracket made form 25mm x 1mm

aluminium tape – it allows the controller to be easily taken in hand without

pushing the telescope mount.

Field tests

My drive was tested after

the modification during several nights of observing. The modification proves to

be very helpful – with my 3.5m cord I can easily take hand controller to the

eyepiece and use it to center a planetary nebula in a field of a

high-magnification eyepiece, while moments later I use the map lamp to look in

my Star Atlas 2000 for next object to observe.

And the close up of the

connections to the stepper driver:

I didn’t try auto-guiding

yet, but I think it will be possible with this modified drive, as I have

already checked the drive reaction. First, I put the mount slightly out

of balance in RA to make the motor work “upwards” – this eats any gearbox play.

Then, I simply use the RA+ button at 2x speed to sleeve the scope westwards,

and use pause button (and the diurnal motion of the sky) to sleeve the scope

eastwards to correct the periodic error. From my eyepiece impression at over

200x, the mount reacts almost immediately, definitely a couple of times faster

than if you reverse the direction of the RA drive! I think a similar trick with

slight imbalance can also work for DEC axis. Also, it may be easier to track in

declination if you correct only in one direction – very slight offset of the

polar axis off the true celestial pole can do this, but will also limit useful

exposure times due to the field rotation.

Final notes

Just a few final notes on

building electronic devices:

- It always pays to buy 1 – 2 more components – if

one get damaged during assembly, you will save a trip to the shop.

- Use only new components. If a component has any

of physical damage, discard it. Even if it works initially, the

probability of failure is greater.

- In case of any doubt, always check components.

Even simple multi meter will help. Resistors can be easily checked for

their values. Discard any resistor if the value is outside +/-20% of the

nominal value. Diodes can be checked using diode checking setting on the

multi meter. If you do not have one, you can use 9V battery, LED and

1.5kOhm resistor in series. For transistors the best way is to check their

current amplification coefficient. Switches and relays can be checked

using circuit continuity checker.

- While working with the main board of the stepper

controller circuit, I recommend to use an ant-static device to prevent

damage to the micro-controller.

- Use small soldering iron. Precision 15 W model

is the best choice.

- Plan assembly in advance. Some components may be

easier to mount on the PCB if they are soldered first.

- Always perform lots of tests after new component

or few components are added. Any failure can be contributed to the

components most recently added, so check them first. Isolating a problem

in a complex circuit may be quite difficult.

- Faults may be contributed to failed components,

bridges shorting traces on the PCB, small hair-like wires shortening soldering

points, broken wires inside the insulation (rare), broken joints of wires.

- Mechanical components (plugs, sockets, switches,

buttons, relays) tend to fail first.

- If the soldered components are dirty, if you

solder to shortly or if the temperature of the iron is to low, you can get

a “cold joint”. Cold joint may look as a proper one, but will contribute

noise and eventually will break. For good joints, the soldering time

should be approx. 2 – 3 seconds.

- Do not overheat components – the soldering time

should not be longer than few seconds.

- Large components (e.g. capacitors) tend to tear

joints away from the PCB if exposed to shock - due to their large mass. To

relive some stress from joints, you can secure these components by

alternative means – e.g. using silicone adhesive. If a component has

mounting holes – simply use small machine screws and nuts to secure it in

place.