CG-5

hard wood tripod

By Paweł Łańcucki, Pawel.Lancucki@pl.ibm.com

I use CG-5 mount from

Celestron for about one year. After fixing initial problems with poor

mechanical performance due to stiff grease and bad surfaces finish (see details

on the AstronomyBoy web page), the mount proved quite useful with a range of

telescopes, including 90mm f/11 achromatic refractor, 170mm f/7 Newtonian and

100mm f/10 Maksutov.

However, there was still a

number of things which remained annoying with the mount, the worst being the

poor aluminium tripod, which – while adequate for my small Mak, did not support

properly the heavier Newtonian.

After some considerations

and planning, I decided to adapt a heavy-duty hardwood tripod for my mount.

Ready made hard wood tripod – a bargain

My initial idea was quite

similar to many others – just replace the aluminium legs with ones made from

hard wood – preferably high quality oak. Then, while dropping to a local photo

exchange, I noticed an old theodolite tripod. Theodolites are devices used by

geologists, geodesists and civil engineers to accurately measure distances and

angles in the field. Although the theodolite head (the measuring device)

weights only around 10 kg, the tripod must be very heavy and stable, because it

must support device used to measure minute angles, in order of single arc

seconds. Sounds familiar? The tripod I found was made from aluminium and

hardwood, with three heavy, full thickness and regulated length legs connected

by a triangular central hub. It looked solid. I set it up just by spreading the

legs and tried to put all my weight on the tripod (100 kg). I could not detect

any flexure or wobble. Well, this was a bargain. It was mine for just below

$50.

At home, I inspected the

tripod thoroughly. It had no technical flaws, just a lot of traces of wear and

tear and a lot of dirt, so I decided to dismantle and clean it. Old paint was

removed from all wooden parts using chemical solvent and a lot of sand paper,

than they were treated with a polyurethane primer and two layers of clear

marine-grade finish. All steel and aluminium parts were also cleaned and painted

with a primer and two layers of anti-corrosive black paint (Hamerite made in

UK). Well, it started to look good:

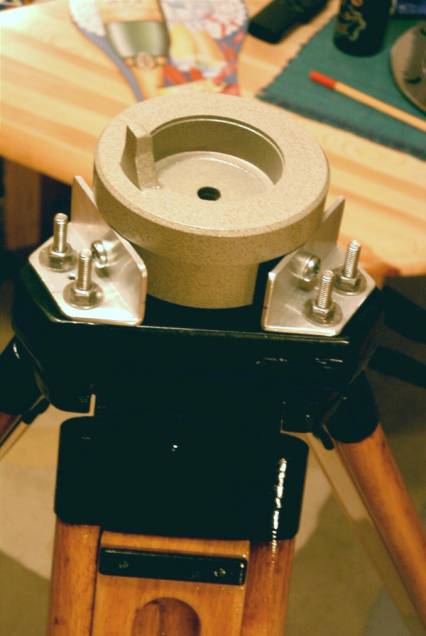

Adapting for CG-5

Having the tripod done, I

had to decide how to attach the mount head. I have purchased a pier adapter for

GP mounts from Orion Optics UK (www.orionoptics.co.uk). GP and CG-5 mount heads

fit this adapter in the same way they fit the central hub on the original

aluminium tripod. The first adapter get lost in the mail, but Orion Optics

promptly issued another one, which I received two weeks later. To mount adapter

to the tripod head, I used two triangles, each made of two layers of 15mm

plywood glued together with water-proof carpenter’s glue. Upper triangle is

slightly larger than the tripod head – just large enough to securely catch

metal L brackets holding the GP adapter. Lower triangle must be smaller to fit

under the tripod head, between the legs. Both triangles are coupled together

using three 80mm M8 bolts, with the tripod head / central hub squeezed between

them.

GP adapter is attached to

the upper triangle using six 40mm M6 bolts with heads locking in the wood.

Using carpenter’s 20mm bore, I made six holes 4 mm deep to capture bolt heads within

the thickness of the upper triangle. Three aluminium L brackets were cut from

30 x 30 angle stock with 3 mm walls. Top corners were cut-off and all corners

and cuts were sanded and polished with a high-number sand paper.

Because the L brackets are

angled to each other, they form a very stiff coupling between the GP adapter

and the upper triangle. Obviously, thicker walls would be even better. In my

case there was a 3mm gap between the adapter and upper triangle due to the size

of available L stock, so I have put a large O-ring made from hard rubber in it

to even better couple the two elements and to better transfer vibrations down

to the ground. Finally, I attached a hand knob to a 120mm M10 bolt, which holds

the mount head in the adapter. All bolts, nuts and washers are stainless steel

to avoid corrosion.

In total, it took some 6

evenings of work, of course the duration of the entire project was longer (some

4 weeks) because I had to wait for many layers of paint to dry.

After a quick test in the

field I noticed that I need to hold the legs together – especially if setting

the tripod on a smooth surface like tiles on concrete – the solution was to

connect the legs with 3 meters of a strong string.

Some more pictures from the

field tests are shown below.

CG-5 equatorial head placed

on the tripod, counterweight shaft attached, standard 5 kg (11 lbs) and two

custom-made 2.5 kg counterweights to balance my heavy 7 inch f/7 Newtonian

scope:

My Newtonian OTA attached to

the mount using standard dovetail adapter and custom made “tube rings” – rather

a length of 2mm thick 25mm wide aluminium tape and some pieces of oak wood:

When assembled, the

telescope draw attention of neighbouring children – quite eager to have a look

at the sky even in daylight (see the front cover) and then at Mars late in the

night:

Final results

How to evaluate final

result? Well, try to set your scope up on jelly. And then move to concrete. I

still need to eliminate some play in the mount head, but the difference is impressive

already. Any vibrations at the eyepiece of my (rather heavy – 8 kg) Newtonian

are dampened within 1 – 1.5 seconds!

Drawbacks

There are two. First, the

hardwood tripod is substantially heavier than the aluminium one, it weights

around 15 kg in total. Second – at its lowers position, it is still about 25 cm

higher than the original tripod, so some people may have trouble to reach the

eyepiece of a Newtonian telescope in some positions if the tube is longer than

90 cm – and this is true in my case. A one-step ladder however cures this

problem, and overall improvement in stability is definitely worthwhile.

Furthermore, new, higher tripod is even more convenient for refractors!

I have a future plan to add

additional brace between the legs – mostly to prevent them for spreading too

far if the scope is set on a slippery surface. It will also support an

accessory tray, which will hold eyepieces, filters and power supply box (see

further description).

And what about the original

tripod? Well, it is not entirely hopeless. I can still use it if I only plan to

use the Mak scope, in particular to make it more portable for observing in the

field. Also, I plan to use some rainy weekend during this summer or autumn to

build a parallelogram for my 16 x 80 binoculars, and this would be a great

tripod to put it mount on.